General Specifications

Besides building world class Coil Processing Equipment, we can also assist you with many other aspects of your project. Whether you are buying your first Cut-To-Length, Blanking, or Slitting Line, or you are already a seasoned professional, it can be an intimidating process. Will the machine fit in my building? Do I have enough power? Who do I call to design the foundations (based on soil conditions) and provide a PE stamp (Professional Engineer) if it is required? Who is going to provide the foundation work and install the line? Even if you have the personnel to perform and/or you contract these tasks, it still consumes a lot of time and manpower.

Stress-Free Pre-Engineering Services

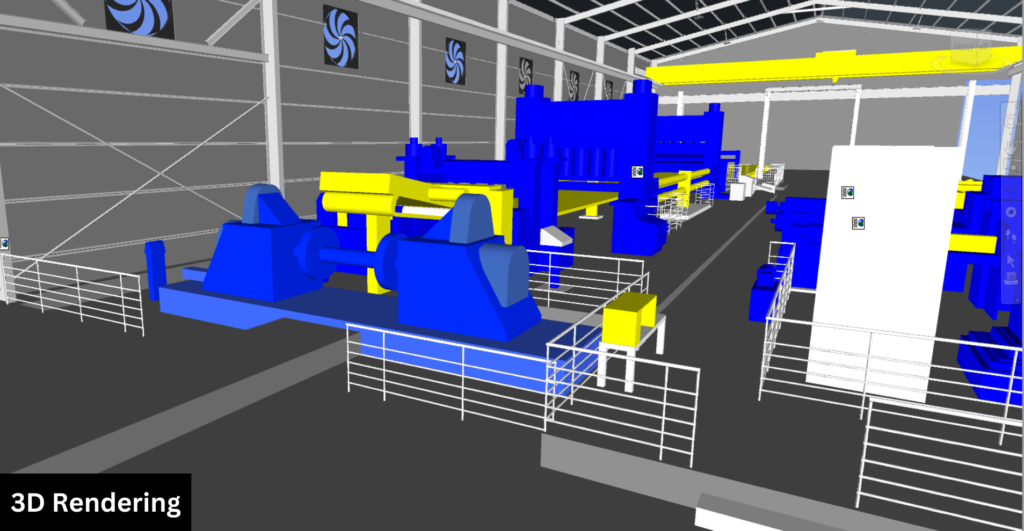

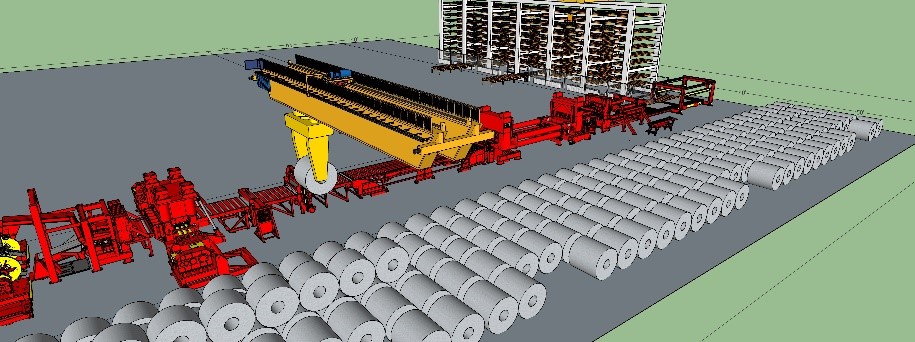

Red Bud Industries’ Pre-Engineering Services will take the stress out of your next project. Is the machine going into an existing building, but you do not have good drawings that are up to date nor are they in an electronic format? We can help. Using the latest 3D laser scanning technology, accurate and detailed building imagery can be delivered that will provide building dimensions as well as the location of existing columns, doorways, pits, conduits, drive cabinets, and pretty much anything else in the building, including your existing equipment. With this information, you can make informed decisions based on precise and reliable data that can be converted into an electronic building layout which can be subsequently used to position new machines in your facility. This lets you see areas that might create issues with the installation, such as crane locations, building pillars, truck bays, or rail sidings. This will allow you to make whatever adjustments necessary to the layout to avoid issues during construction and the installation of the equipment.

Your existing power supply can be reviewed and details of what will be needed for the new equipment can be provided. And if necessary, the new switch gear can be provided and installed too! Once we have determined the position of the equipment in your building, your foundation would be designed, the necessary certification would be provided, and then the concrete work and installation of the line would be completed.

We are also experts in the design and layout of service centers. Whether you are building an addition or a whole new facility, adding one new machine or several, we can help you optimize your plant layout to assure you get the most out of your investment. We can work with you to optimize material flow through your plant. In addition, we can suggest the best locations and space requirements for incoming material, machine placement, and outgoing material storage.

Highlights

- Laser Scanner measures the interior of the building and locations of the columns.*

- Provides precision reliable data that can be used to generate 3D imagery.*

- Services available include foundation work and equipment installation.*

- Includes foundation design and PE stamp if requested.*

- We also design building layouts to ensure efficient work flow and material handling.

We can help you to design a new facility, add an addition, or use an existing space. We can also help to optimize workflow and material handling.

Pre-Engineering Services can include foundation design and provision of the necessary certifications.

Once the machine arrives, installation services are also available to make sure it is done right and in a professional manner.

*Pre-Engineering Services may be performed by third party contractors, hired directly by Buyer. While Red Bud Industries will assist Buyer with such Pre-Engineering Services, Red Bud Industries, Inc. does not guarantee the accuracy or quality of work performed by third party contractors.